The Story of Quincalux.

The story of Quincalux began in 1942, when Werner Desschans opened a small workshop in the heart of Kortrijk, West Flanders, Belgium. Following in the footsteps of his father Georges, a skilled blacksmith, Werner carried forward the family craft. At the time, reception grilles for banks were in high demand, and this product laid the foundation for the company’s early success.

After World War II, Belgium entered a period of reconstruction. With it came a growing need for everyday essentials like handrails, coat racks, door handles, and pulls. Quincalux responded to this demand, expanding both its product range and its reputation.

From the mid-1960s onward, under the leadership of Carl Desschans, brass became the material of choice. The workshop grew, and the team expanded. A national distribution network was established, with representatives visiting clients across Belgium. This period of growth led to a second relocation—this time to the company’s current home in Wevelgem.

In the mid-1990s, Carl’s son Lorenzo joined the business, bringing with him a new perspective. Under his guidance, Quincalux began exporting architectural hardware and collaborating with Belgian designers. The brand evolved to feature more contemporary styles, while staying true to its heritage of craftsmanship and brass expertise.

In 2024, a new chapter began. Martine Reynaers and her daughter Claire Juliard took over the reins of the family business, with Lorenzo continuing in his role as production manager, sharing his knowledge and experience.

Today, this new generation of entrepreneurs leads Quincalux with a clear vision: to grow both at home and internationally, offering well-designed, high-quality, and ecological products. Their ambition is to make Quincalux the reference for architectural hardware in Belgium, across Europe, and around the world.

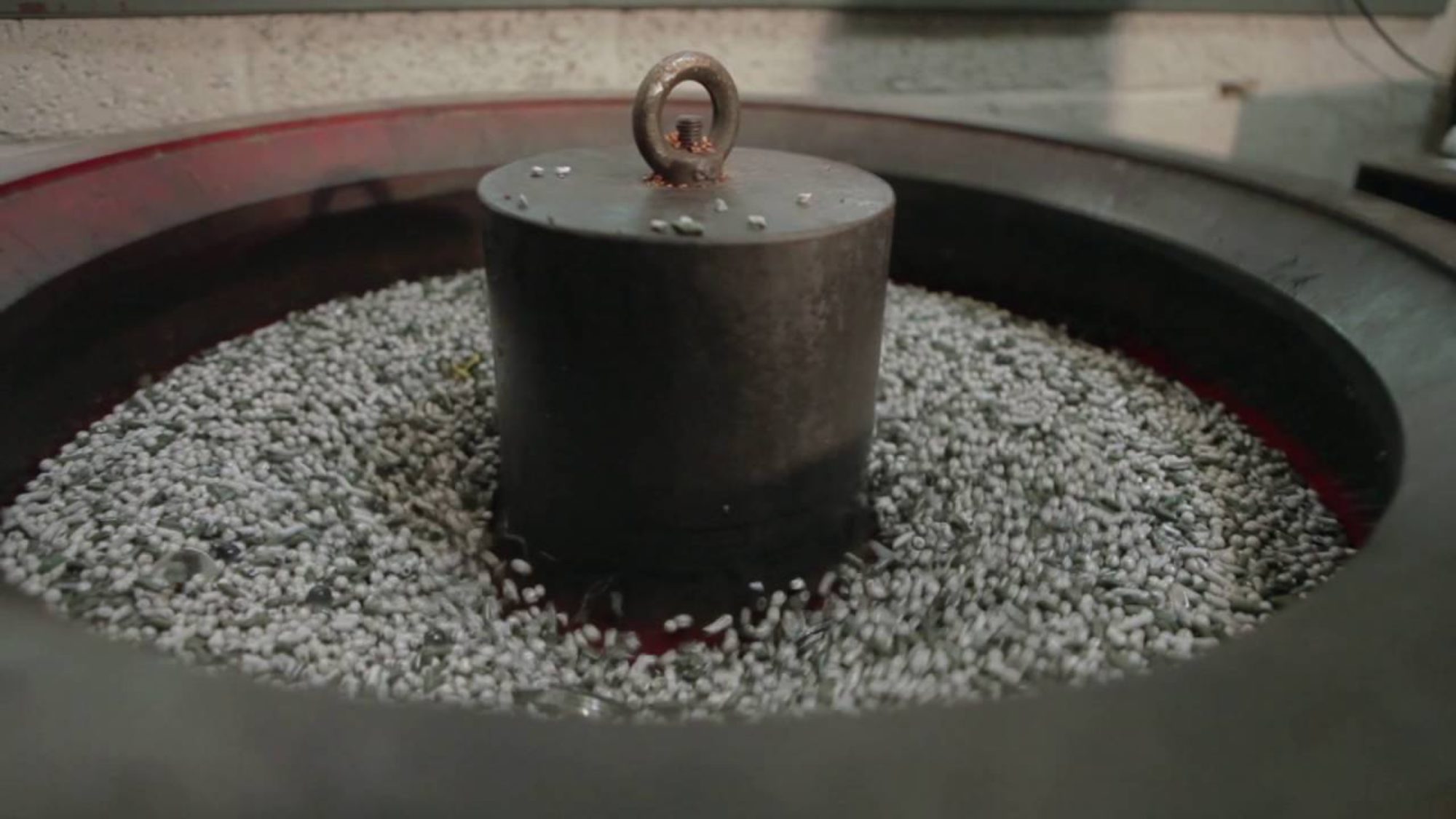

Handmade in Belgium

99% of our products are manufactured in our factory in Wevelgem, Flanders.

This is one of Quincalux’s greatest strengths: complete control over our production chain.

From machining to polishing, from sandblasting to surface treatment, and all the way to varnishing — every step is carried out in-house with recognized expertise.

Every day, raw brass is transformed on-site into finished pieces, ready to enhance your spaces.

We are proud to open the doors of our factory to visitors. Feel free to contact us at info@quincalux.com to discover our showroom and workshop.